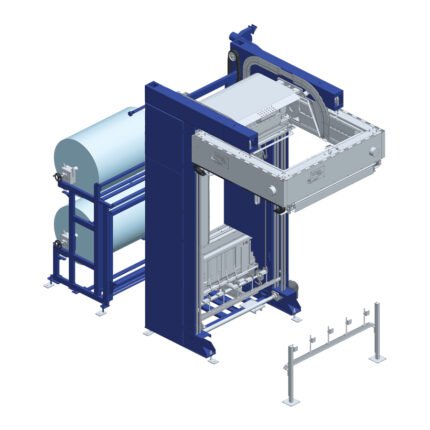

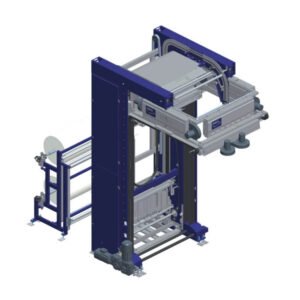

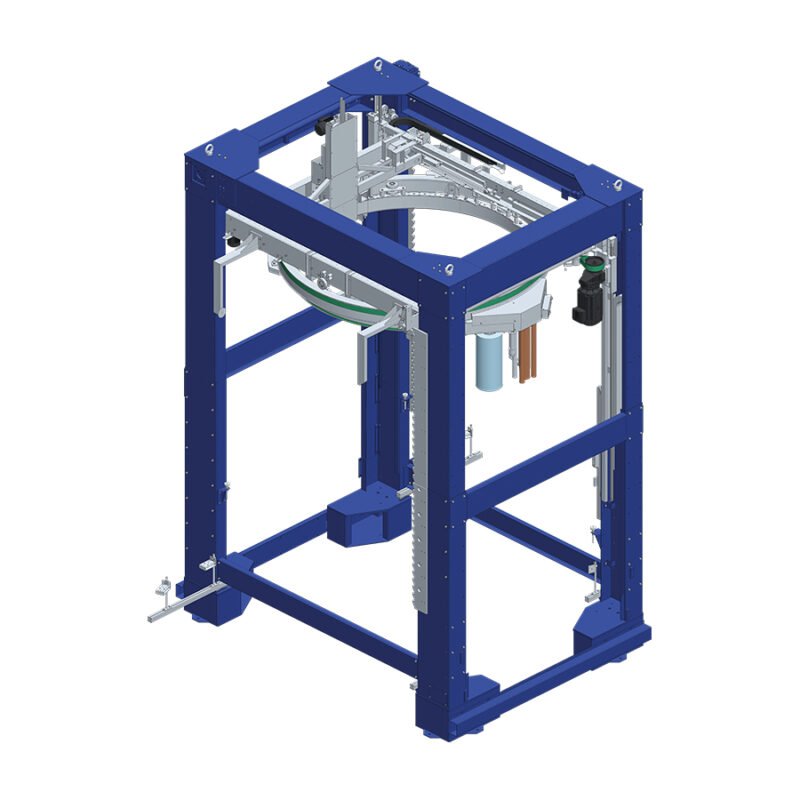

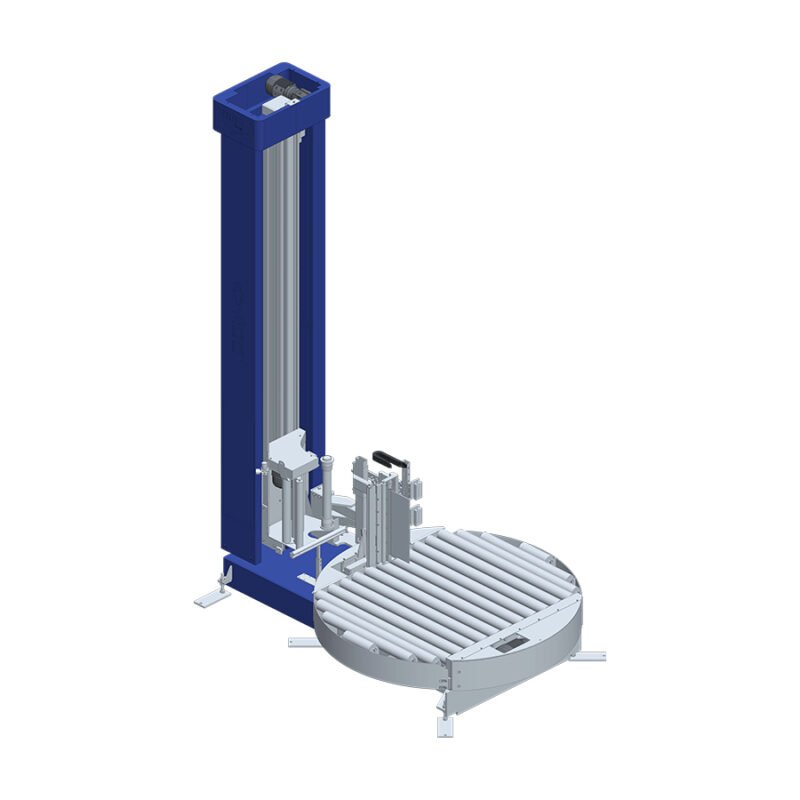

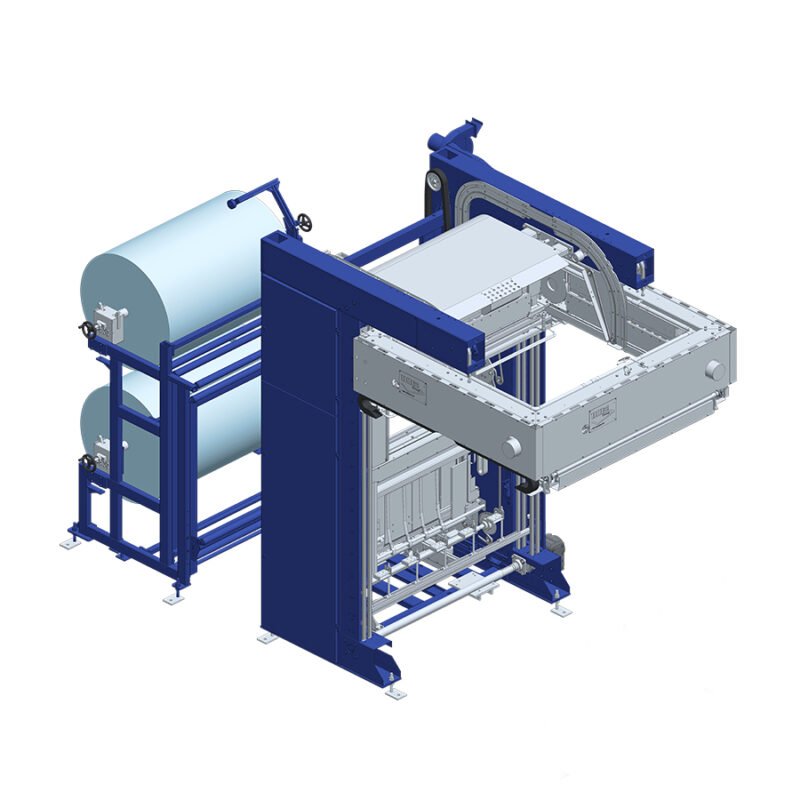

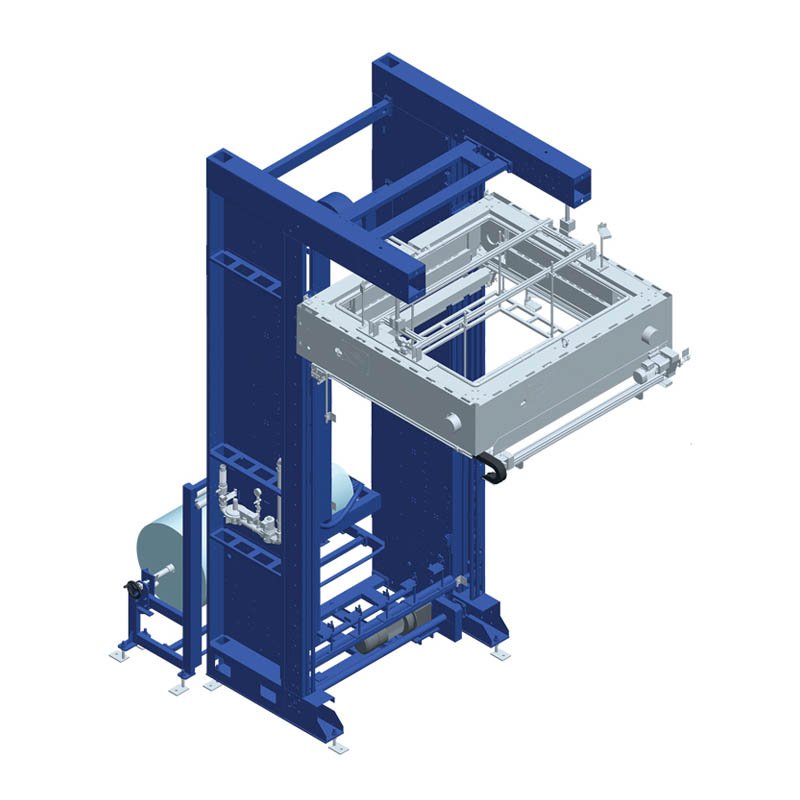

Automatic Thermo Hooding Machine / AT55

The Model AT55 automatic hooding machine is a combined automatic machine that uses a single workstation to shrink-hood the products to be packaged, especially designed for the hollow glass industry.

The machine uses coils of tubular thermoshrinking film with side gussets. The coils can be 1, 2 or 3 depending on the chosen version.

The film is shrunk on the product by a ring-like gas oven.

The production capacity of the machine is up to 60 packs per hour.

All use and maintenance, automatic and manual functions, are controlled by a PLC.

The operator needs to be present only to change the film coil, even though it is advisable that he also be present to check that the product to be wrapped enters the machine correctly.

Categories: Packaging Machinery, Thermo shrinking Machines

STANDARD MACHINE CHARACTERISTICS

- Film Type: polyethylene thermo

- Thickness: 70–180 micron

- Coil diameter maximum: 1000 mm (optional)

- Coil weight maximum: 1000 kg

- Electrical Supply: 400 V, 50 Hz, three-phase

- Installed Power: 25,5 kW

- Air Pressure: 5,5 ÷ 7 bar

- Gas type: propane or methane (butane)

- Gas Pressure: 200 mbar -15% / +5%

Available options:

- Special motors for productivity up to 80 packs/hour

- Double or triple coil holder

- Coil up to ø1000 mm

- Lifter (to seal the film under the pallet)

- External temperature sensor

- Gas pressure reducer kit (Max pressure input 4bar)

- Gas pressure reducer kit (Max pressure input 8bar)