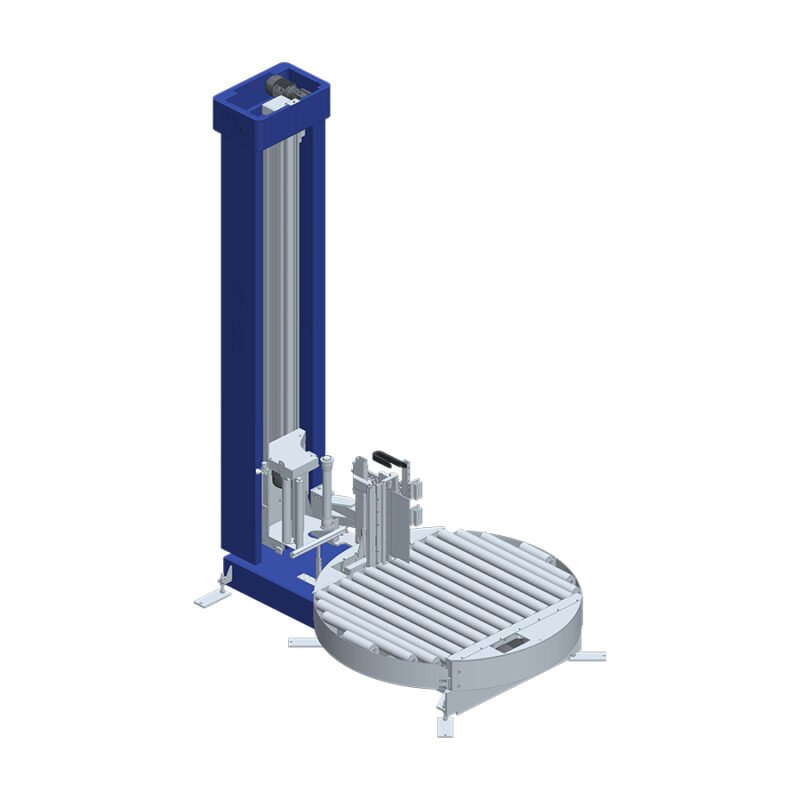

AV300 Rotary Table Wrapping Machine

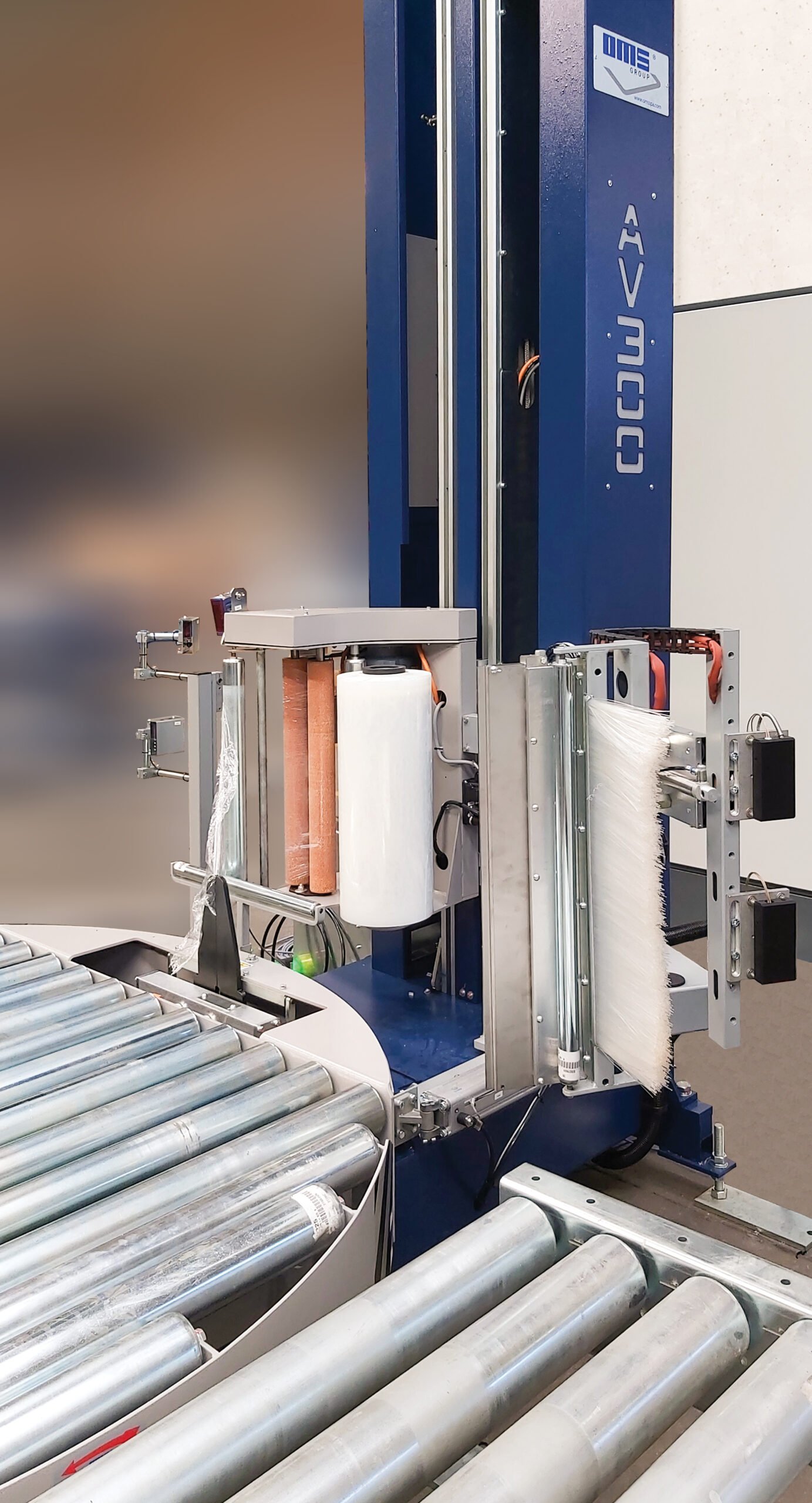

rotary table wrapping machine has been developed for medium-capacity production, complete with a motorized roller and a totally automatic device for film stapling, cutting, and sealing.

Furthermore, the motorized pre-stretch device feature greatly reduces film consumption. Model AV300 may also be fitted with a completely automatic sheet insertion device that, during the pack pre-wrapping stage, undertakes to unroll the necessary amount of film and, after receiving consent from the winder, undertakes to place it at the top of the pack. At the end of the depositing operation, the wrapping machine completes its winding cycle and expels the pack from the roller.

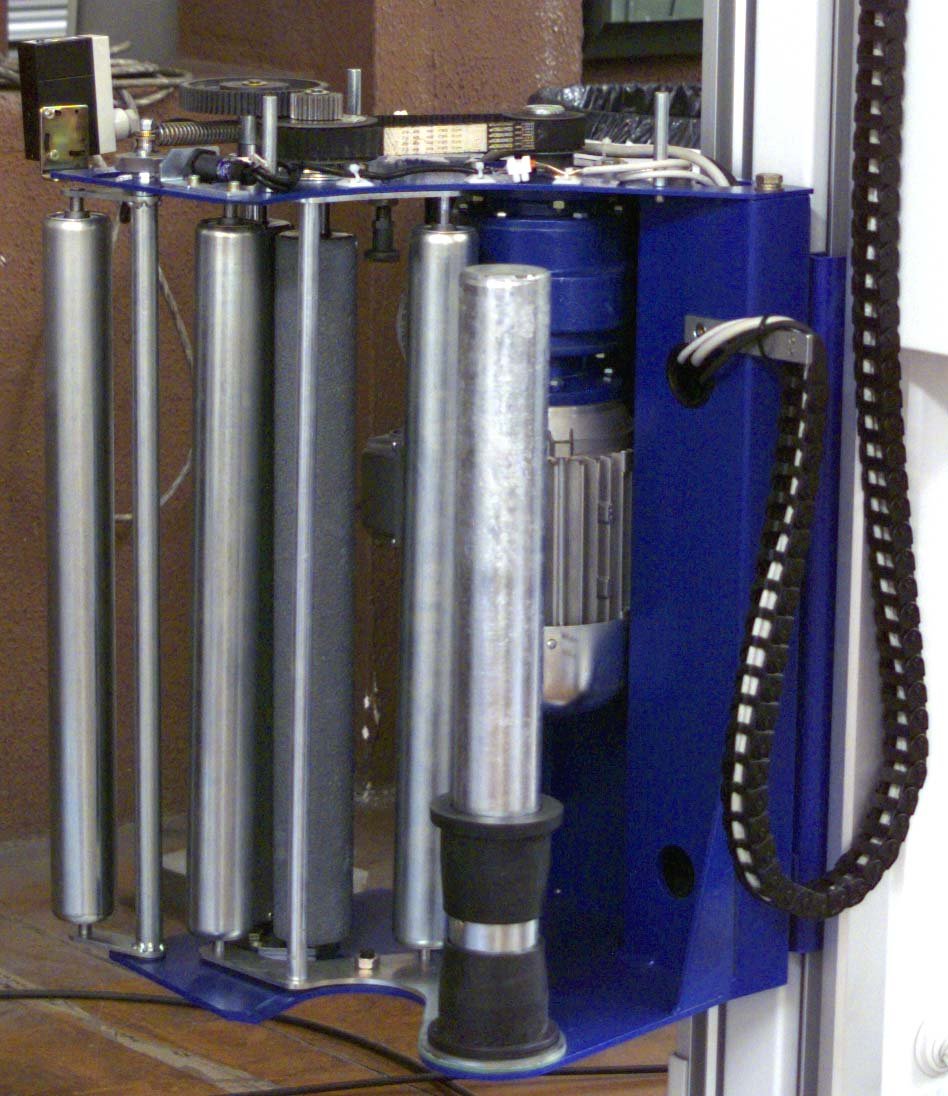

The electromechanical pre-stretch uses an electromagnetic brake feed by an electronic card, which tensions the film. The motorized pre-stretching sensibly reduces film consumption since it stretches the film by about 4 times its initial length.

The machine is also equipped with a touch-screen operator panel with which it is possible to set the winding program, the number of wrapping turns, film overlapping, and film tensing on the product. Moreover, it provides machine diagnostics and important information such as cycle times, film used for each pack, wrapped pack counter, and execution times.

The machine can also be equipped with optional devices such as a press to hold unstable loads, a top sheet dispenser to seal the upper part of the pack with a waterproof system, and, if needed, a conveyor with two or more chain branches.

Options available:

Top press, stabilizer

Roping device

Categories: Automatic, Packaging Machinery, Stretch Wrapping Machines

STANDARD MACHINE CHARACTERISTICS

- Max pallet weight: 2000 kg

- Pallet size: W 800-1000 x L 800-1200 mm - H 500 - 1800 mm

- Height rotary table: 500 mm

- Ourly output up to 35 packs/hour, according to the wrapping cycle

- Electrical supply: 230V/400V 50 Hz

- Installed power: 3 kW

- Air consumption- cycle: 30 Nl