Automatic Hooding Machine / AT53 GLS

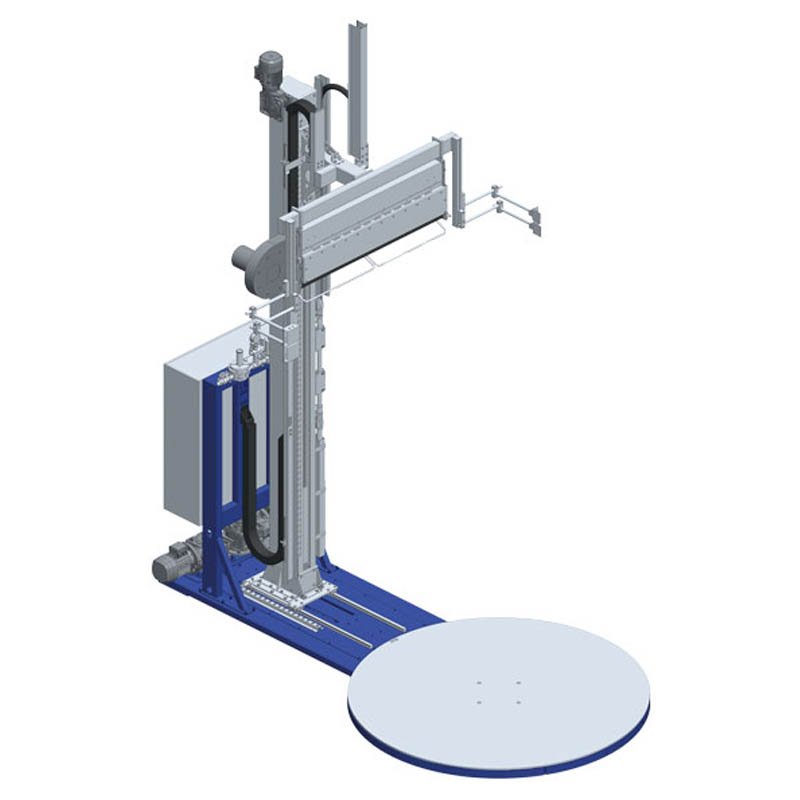

The automatic hooding machine model AT53 GLS is a combined automatic machine that uses a single workstation to shrink hood the products to be packaged, specially designed for the hollow glass industry.

Its hot air generation system through linear gas burners is designed to work either with methane or propane gas (type approval number DG2217BL0557 issued by the German Gas Institute is valid in all EU countries).

Hood preparation takes place on the back part of the machine while hooding and thermoshrinking take place on the front side.

The AT53 GLS machine is available with one, two, or three coils of tubular film of the same or different sizes. All automatic and manual operations are managed through a PLC.

The operator’s presence is necessary only to change the film coil

Categories: Packaging Machinery, Thermo shrinking Machines

STANDARD MACHINE CHARACTERISTICS

- Film Type: polyethylene thermo

- Thickness: 60–200 micron

- Max coil weight: 1000 kg

- Max coil diameter: 1000 mm

- Max hourly output: 80 packs/h

- Electrical Supply: 400 V, 50 Hz, three-phase

- Installed Power: 15kW

- Air Pressure: 5,5 ÷ 7 bar

- Gas Type: Propane or methane (butane)

- Gas Pressure: 200 mbar (-15%/+15%)