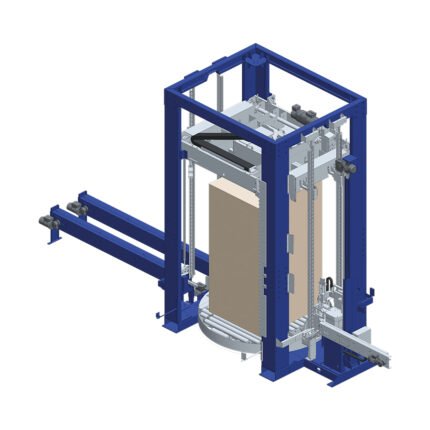

Vertical Press/Strapping Machine/ Press Master GLS

Press Master GLS

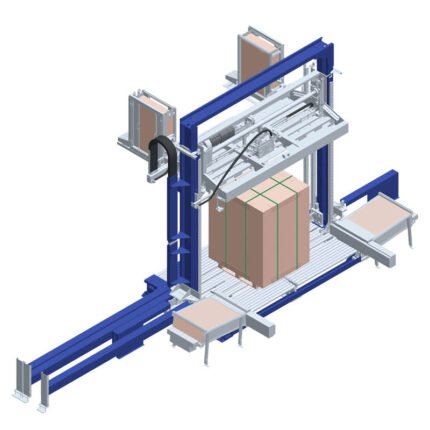

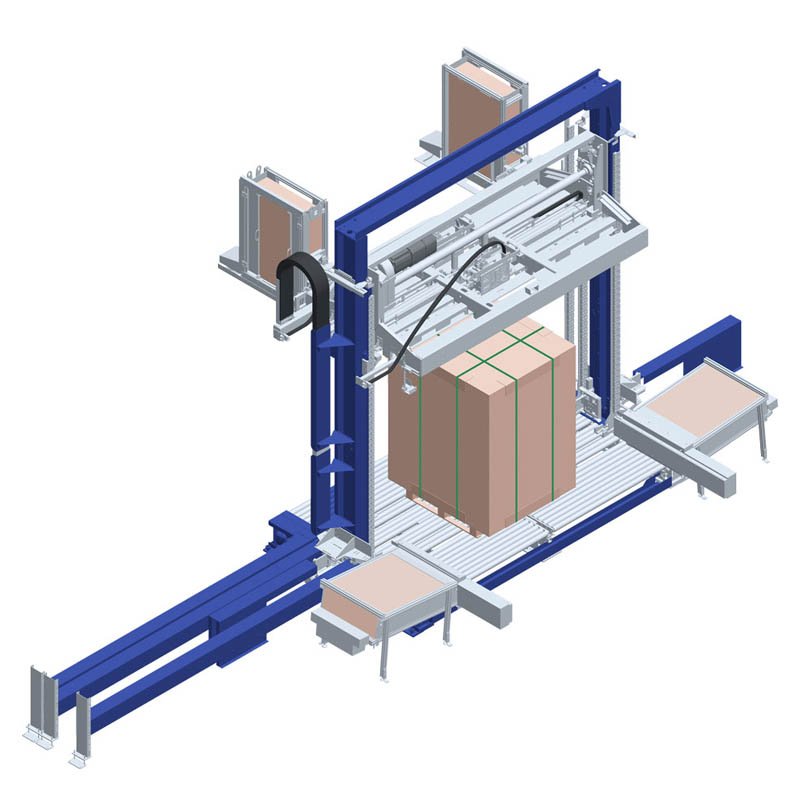

The vertical press/strapping machine model Press Master GLS automatically applies vertical straps to palletized products that need to be kept together during transport, handling, and warehousing.

Specifically for the hollow glass industry, the system was conceived and designed with a compression force of up to 2,4 t. It was constructed with a rack and pinion drive and an inverter to adjust the press plate speed up to 200 mm/sec.

Either OMS conveyors or an integrated build into the customer’s conveyor system can be used with the basic design.

It can be equipped with the SONIC Plus, TR1400 / TR1400HD, and TR1800 strapping heads (our international patents), which automatically perform the operations of launching, recovering, tensioning, welding, and cutting the strap.

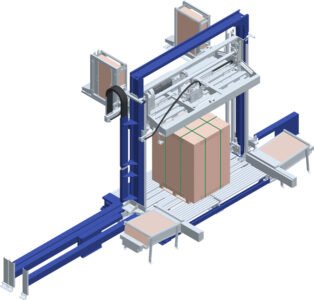

Using a polyester or polypropylene strap, this machine can simultaneously perform vertical strapping in a single cycle, depending on the configuration selected. It can be added to existing automatic lines where it exchanges input and output signals with the devices installed upstream and downstream the line

STANDARD MACHINE CHARACTERISTICS

- Strap Type: PP or PET

- Applicable strapping heads: SONIC Plus, TR1400, TR1400HD, TR1800

- Compression force: Up to 24.000 N

- Installed Power: 5.5 kW

- Electrical supply: 380-415V, 50Hz, three-phase

Available options:

- Service function (hinged 90°)

- Closed lower strap tracks

- Preselection pallet height

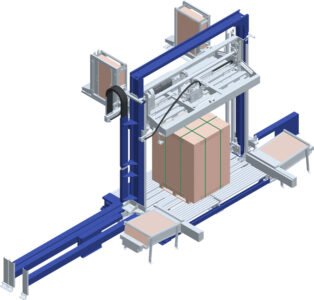

- Fully automatic strap-loading system

- Fully automatic strap exchange system

- Fully automatic strap

- refeeding function

- Pre-scanning the end of the strap

- Automatic safety Lock

- system (Duo)

Chain conveyor - Lifting and turning cross

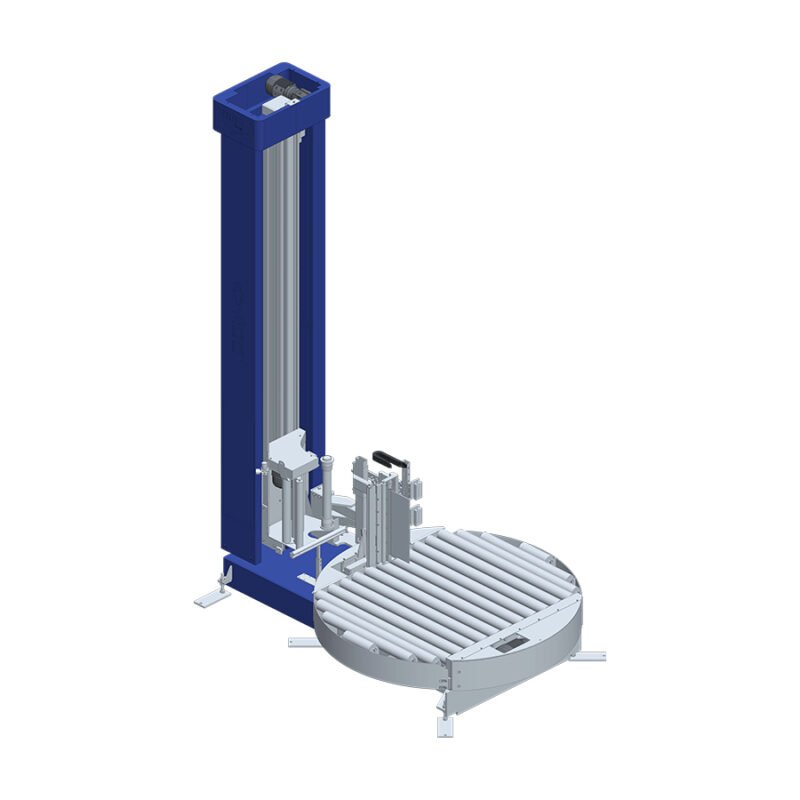

- Turntable with rollers or chains

- Centering device

Machine translation group