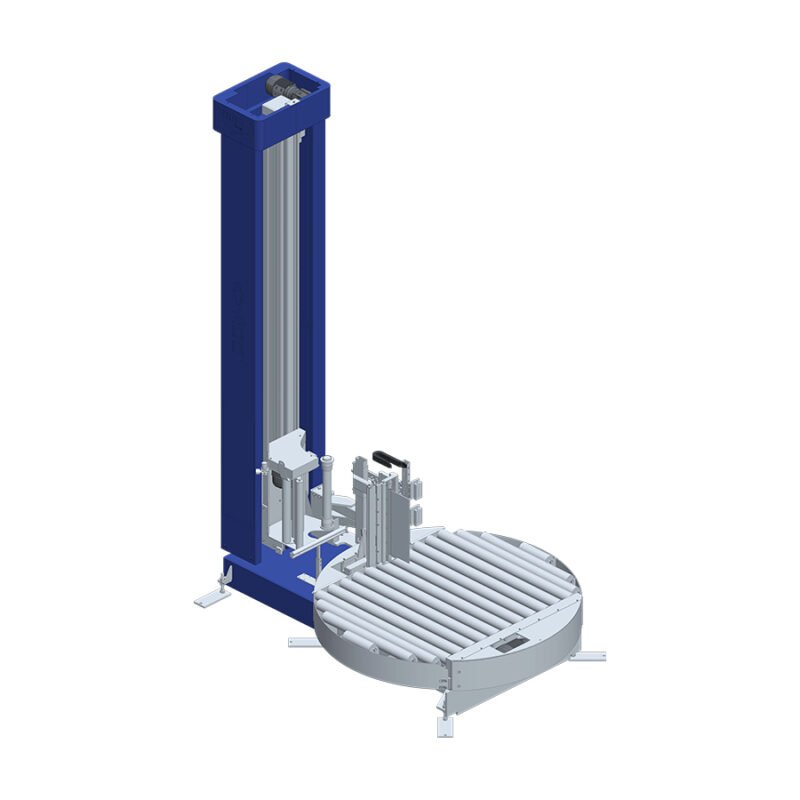

AVR1000 /Automatic Stretch Wrapping Machine

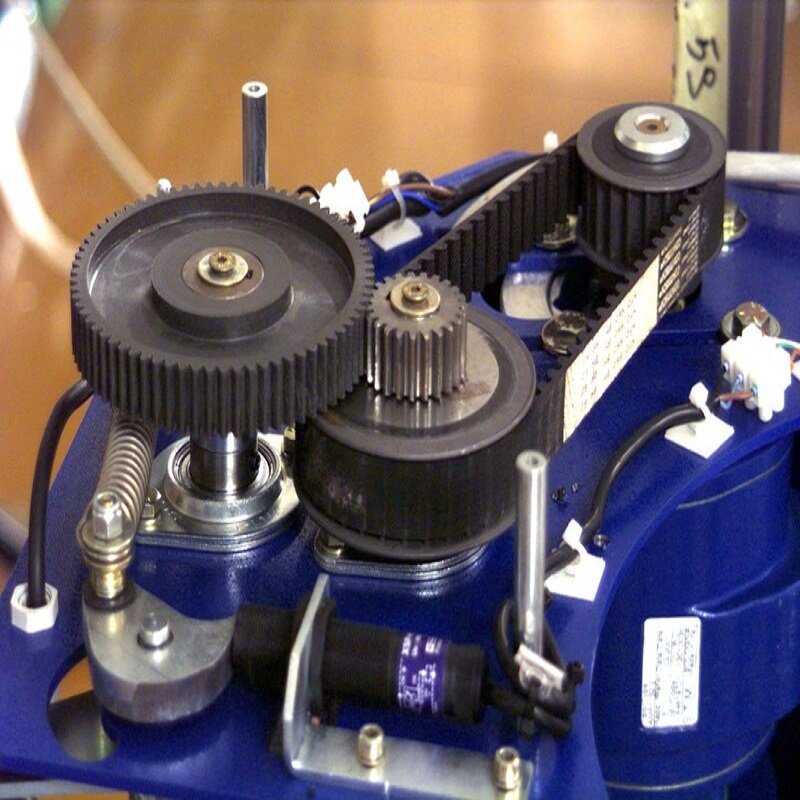

The “new” AVR1000 has been developed with a carbon fiber ring, slip ring contacts, and a pre-stretch carriage up to 300% ratio.

The principle of the “ring” allows for the wrapping cycle to be executed without any movement of the pallet load. As a consequence, the quality and the stability of the pallet load are not endangered and important production capacities remain guaranteed.

Possibility to start and stop the wrapping cycle at any height of the pallet load, allowing specific wrapping programs such as top wrapping and single wrapping.

Strong points: exclusive and patented pre-stretch system, high speed, simplicity, and flexibility. The results are largely increased reliability and reduced maintenance, as well as stable loads with minimal film consumption.

At the end of the cycle, the final film tail is safely inserted under the previous wrap or welded with halogen lamp device (based on option choosen). As results no loose film ends, guaranteeing a perfect finishing as well as no pallet alignment needed as the system detects and moves towards the pallet.

Options available:

– Motorized pantograph top press, stabilizer;

– Gravity stabilizer press;

– Lifting device;

– Single band lower;

– Double twin band lower;

STANDARD MACHINE CHARACTERISTICS

- Hourly output: up to 100 packs per hour (120 packs per hour with twin carriages version)

- Rotation speed adjustable: Up to 54 rpm

- Roll width: 500 mm

- Roll weight: max. 20 kg

- Film thickness: From 15 to 35 microns

- Electrical power supply: 3 Ph, 400V, 50Hz

- Installed power: 9 kW

- Working air pressure: 5,5 ÷ 6,5 bar