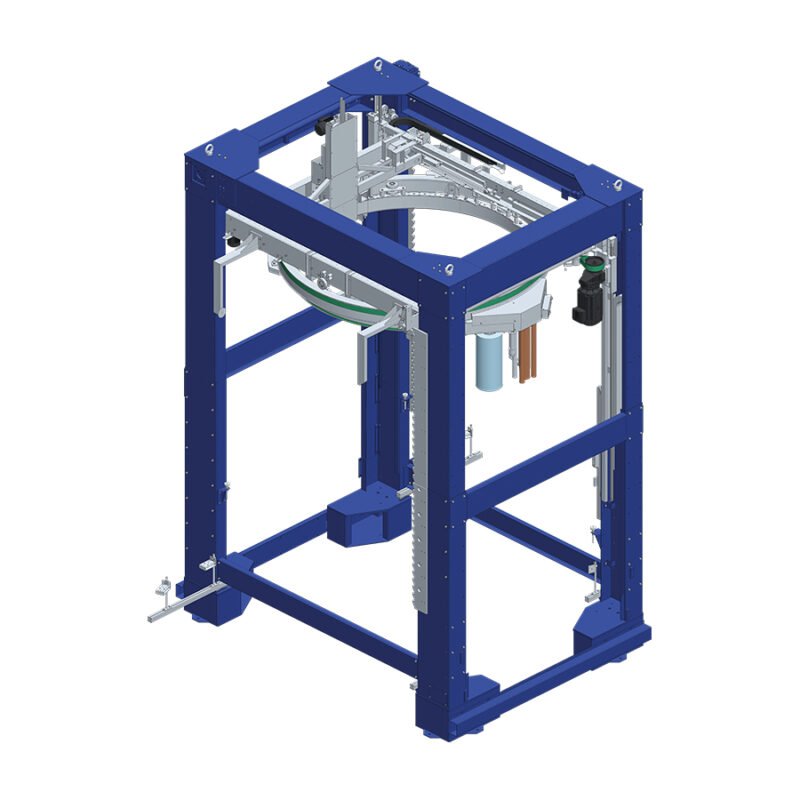

Automatic Hot-Melt Carton Sealer / HM11

HM11

Automatic Hot-Melt Carton Sealer

HM11 is a range of Automatic Hot-Melt Case Sealers.

SIAT produces also a range of Hot Melt Case Sealers. The Hot-Melt technology can only be accepted by automatic machines, due to initial investment and cost reduction applicable on long runs.

Automatic hot melt case sealer with side drive belts and manual adjustment. It is designed to seal with hot melt glue boxes of the same size. The box, coming from a filling station with the bottom flaps sealed, is taken away by drive belts toward the machine where injectors dispense 4 strips of hot melt glue. A system of flap compression rollers provides the proper pressure of boxes. The hot melt sealing machine doesn’t require the presence of an operator except for the glue adjustments and feeding. It is equipped with safety panels to prevent an operator from coming in contact with moving or hot parts.

Categories: Case Sealer, Full Automatic, Packaging Machinery, Taping Machines

Key features

- HM11-TB

Automatic top-flaps-folder device

Manual adjustment on different box sizes by handles

Side drive belts (2 x 75 mm width each)

Drive belts speed 21 m/min.

2 motors kW 0,18 each

The top & bottom glue applicator dispenses the glue on the top and bottom flaps while boxes pass through the machine before top flaps folding

ROBATECH® hot-melt glue applicator on external carriage equipped with 5 Kgs tank, tube and glue dispenser

The glue dispenser adjusts glue temperature and volume

Storing of sealing programs

Timer setting to allow pre-heating adjustment

Box dimensions adjustment

Side safety protections with switches to disconnect electro-pneumatic circuits

Control panel equipped with: main switch start, stop button, stop emergency button and photocells to control the boxes glued

Output: up to 1000 bph

Adjustable working height 500 – 750 mm

OMRON PLC

Box dimensions

Min. L 200 mm W 150 mm H 150 mm

Max. L 500 mm W 500 mm H 500 mm - HM11-T

Automatic top-flaps-folder device

Manual adjustment on the different box sizes by handles

Side drive belts (2 x 75 mm width each)

Drive belts speed 21 m/min

2 motors kW 0,18 each

The top glue applicator dispenses the glue on the top flaps while boxes pass through the machine before top flaps folding

ROBATECH® hot-melt glue applicator on external carriage equipped with 5 Kgs tank, tube and glue dispenser

The glue dispenser adjusts glue temperature and volume

Storing of sealing programs

Timer setting to allow pre-heating adjustment

Box dimensions adjustment

Side safety protections with switches to disconnect electro-pneumatic circuits

Control panel equipped with: main switch start, stop button, stop emergency button and photocells to control the boxes glued

Output: up to 1200 bph

Adjustable working height 500 – 750 mm

OMRON PLC

Box dimensions

Min. L 200 mm W 150 mm H 150 mm

Max. L 600 mm W 500 mm H 500 mm

Advantages

- Automatic top-flaps-folder device

12 different application programs - Ready for integration into automatic lines

- Easy to use

Options

- Other PLC brands on request

- Other hot melt dispenser on request (PREO, NORDSON and other brand)

- Higher legs (AS80)

- Casters (AS77)

- Roller conveyor (RG)

- Extendable conveyor (GTL-GTR)