Best automatic shrink wrap systems FT53 TOP PAL

Automatic shrink wrap systems are among the most important technologies used in many fields, such as the food, pharmaceutical, and electronic sectors. They help significantly in protecting products and improving the efficiency of the packaging process. This reduces the risks of damage or breakage during transport and storage. They also contribute greatly to speeding up production and lowering labor costs. In this article, we will learn about the best automatic shrink wrap systems offered by Hadanco.

What are automatic shrink wrap systems?

automatic shrink wrap systems

Automatic shrink wrap systems show the huge progress happening constantly in the industrial field. They are fully automatic machines used to wrap products using a plastic film. Heat is used to shrink the film tightly around the product. The machine automatically feeds the product, wraps it with plastic film, and cuts the film.

The product is then heated using gas or electricity until the film shrinks perfectly around the item. These automatic machines can greatly increase production speed, especially if they are from a company that makes the best packaging and wrapping tools, like Hadanco, which provides the best automatic equipment.

Advantages of automatic shrink wrap systems for factories

The most important advantages of automatic shrink wrap systems include:

- Helping to protect products from dust, dirt, moisture, and contaminants during transport and storage.

- The films can withstand extreme temperatures, making them ideal for long-distance transport without tearing.

- They are an effective choice for factories with high production because they save time.

- They help reduce costs in the long run because they save on labor and increase production speed.

- They are lightweight, which helps reduce shipping costs and makes them easy to move while saving storage space.

Difference Between Manual and Automatic Shrink Wrap Systems

Manual shrink wrap systems require significant human intervention to start the cycle, place the product, wrap it, or change it. This leads to higher labor costs and slower production speed. However, they cost less than automatic machines. Therefore, they are an effective choice for projects with a specific budget and small production, making them suitable for startups and medium businesses.

Automatic shrink wrap systems work automatically without the need for human intervention. You only need to press a button, and the machine wraps the product. Their production speed is very high. Although they are higher in cost, they help reduce labor costs and increase production efficiency in the long run. Therefore, they are suitable for large projects with high production, large companies, and big warehouses.

How to Inspect an Automatic Shrink Wrap Machine Before Buying

You should choose a reliable place to buy shrink wrap machines. You must ensure the machine is suitable for your product size and check that it works properly. Inspect the external structures of the machine to see if they are made of durable, rust-resistant materials like stainless steel.

You can also check the control panel and electric motors. Ensure spare parts are available for the machine, and test the thermal shrinkage, production speed, heating method, and film type. It is better to use a specialist to inspect the machine before buying to ensure its quality.

Tips for Getting the Best Shrink Wrap Machine at a Suitable Price

Here are some important tips to consider when choosing a suitable shrink wrap machine:

- Compare prices between many companies and choose the right one while considering quality.

- Choose a company with great experience in the field of packaging and wrapping tools.

- Ask about after-sales services, such as maintenance, repair, and spare parts.

- Choose a machine that matches the production capacity and the size of the product being made.

- Choose a suitable film thickness, as increasing the thickness increases costs.

- Consider the conditions of the product after storage or during transport.

- Choose a machine that is compatible with the electricity available at the site.

Why is Hadanco the Best Choice for Shrink Wrap Systems?

automatic shrink wrap systems

Hadanco is a leading company in automatic shrink wrap systems and all other packaging tools. The company has many machines that you can choose from according to your budget and product type.

The company is distinguished by its great experience in the packaging field. It offers continuous discounts on its products and provides them at competitive prices. It also provides special offers on shipping and delivery. The machines are installed and maintained by the best engineers and specialized technicians. This ensures the machine lasts longer and increases productivity without stopping.

The company provides after-sales services like maintenance and repair. It also offers excellent customer service to answer all questions and provide technical support to solve all problems immediately. Therefore, it is one of the most important companies you can rely on for packaging and wrapping tools.

What is the Best Automatic Shrink Wrap Machine from Hadanco?

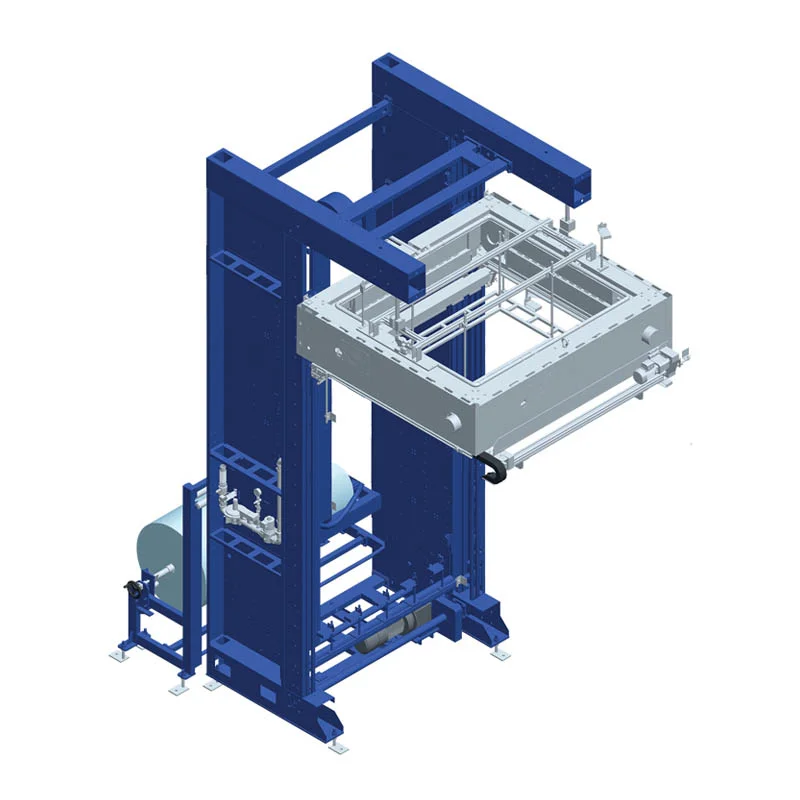

The Automatic Thermoshrinking Machine / FT53 TOP PAL is the ideal choice. This system focuses on wrapping the top part of the load, as it is one of the places most likely to tear during transport or storage. Therefore, this machine ensures the cover is tight on its top moving part. This machine can shrink the film on the product using a ring gas oven and can process about 80 pallets per hour.

It is easily controlled by a PLC (Programmable Logic Controller), through which you can control all use, maintenance, automatic, and manual functions.

Get the Automatic Thermoshrinking Machine / FT53 TOP PAL from Hadanco now

Conclusion

Automatic shrink wrap systems have become important tools that help improve the quality of products in many factories. They speed up production lines and reduce waste during transport and storage because they combine speed, accuracy, and an attractive appearance. This helps increase customer trust in the brand and raises its marketing value. However, you must rely on a reliable company that provides effective solutions in the field of modern packaging, such as Hadanco.

FAQs

What is the best shrink wrap system?

There are many packaging systems to choose from, depending mainly on product size, production speed, and budget. However, Hadanco offers the best shrink wrap systems to suit all industries. Automatic, semi-automatic, and manual tools are available with the best quality and lowest price.

Are shrink wrap systems suitable for all products?

Yes, shrink wrap systems can be used for a very large number of products, including food, medicine, cosmetics, toys, books, and others. They provide protection for all these products against damage, dirt, germs, and dust. Hadanco provides a large range of these machines to suit all industries.