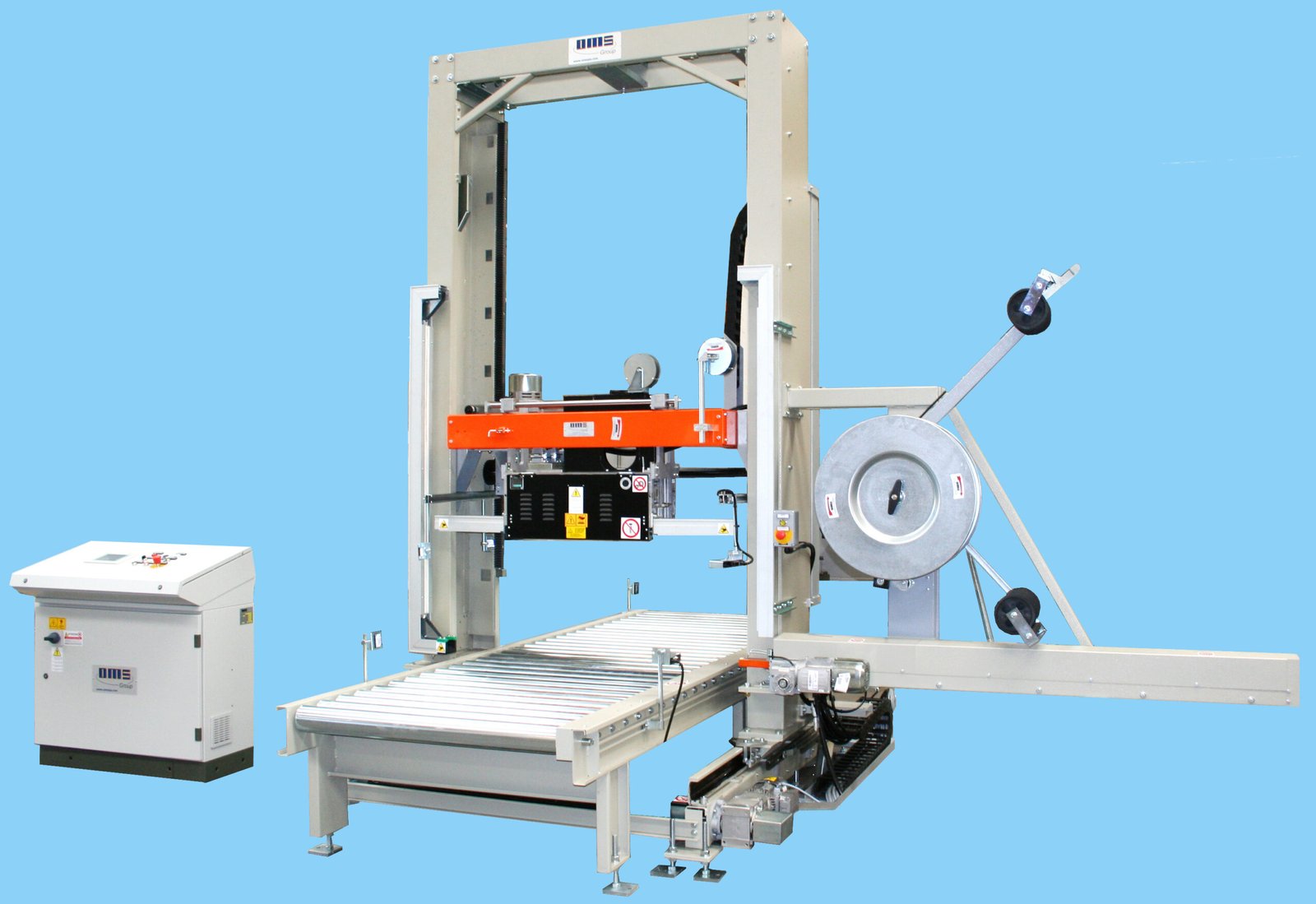

Automatic Vertical Strapping Machine / 08RP

08RP

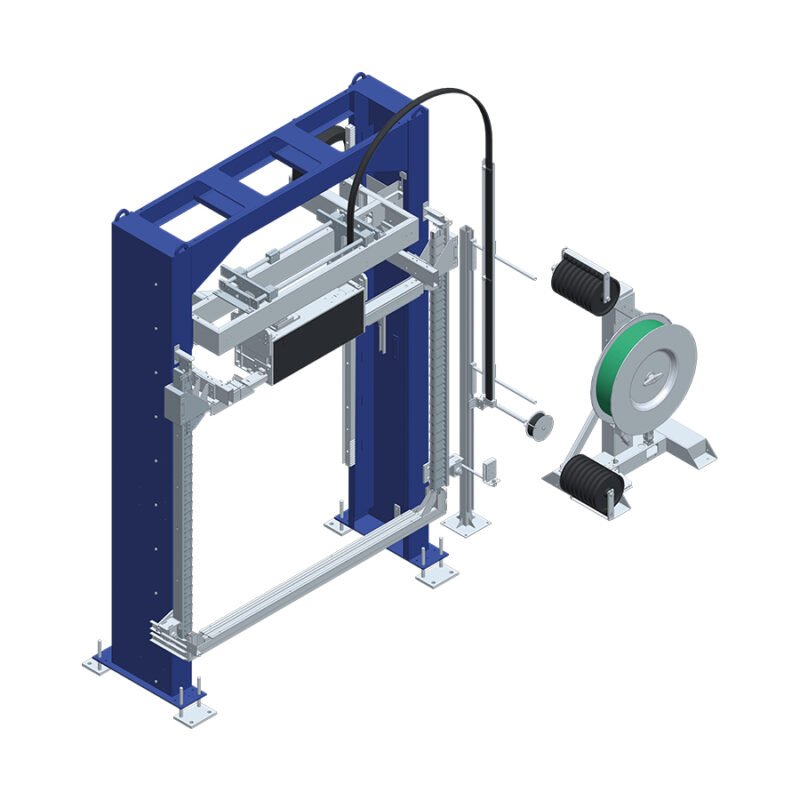

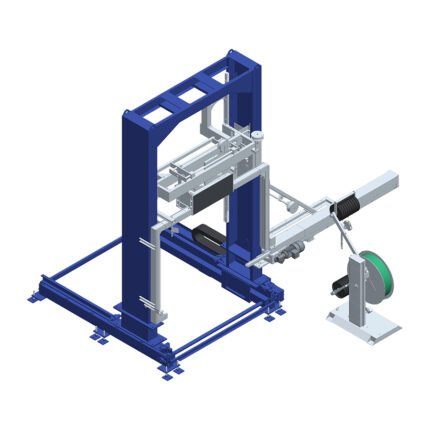

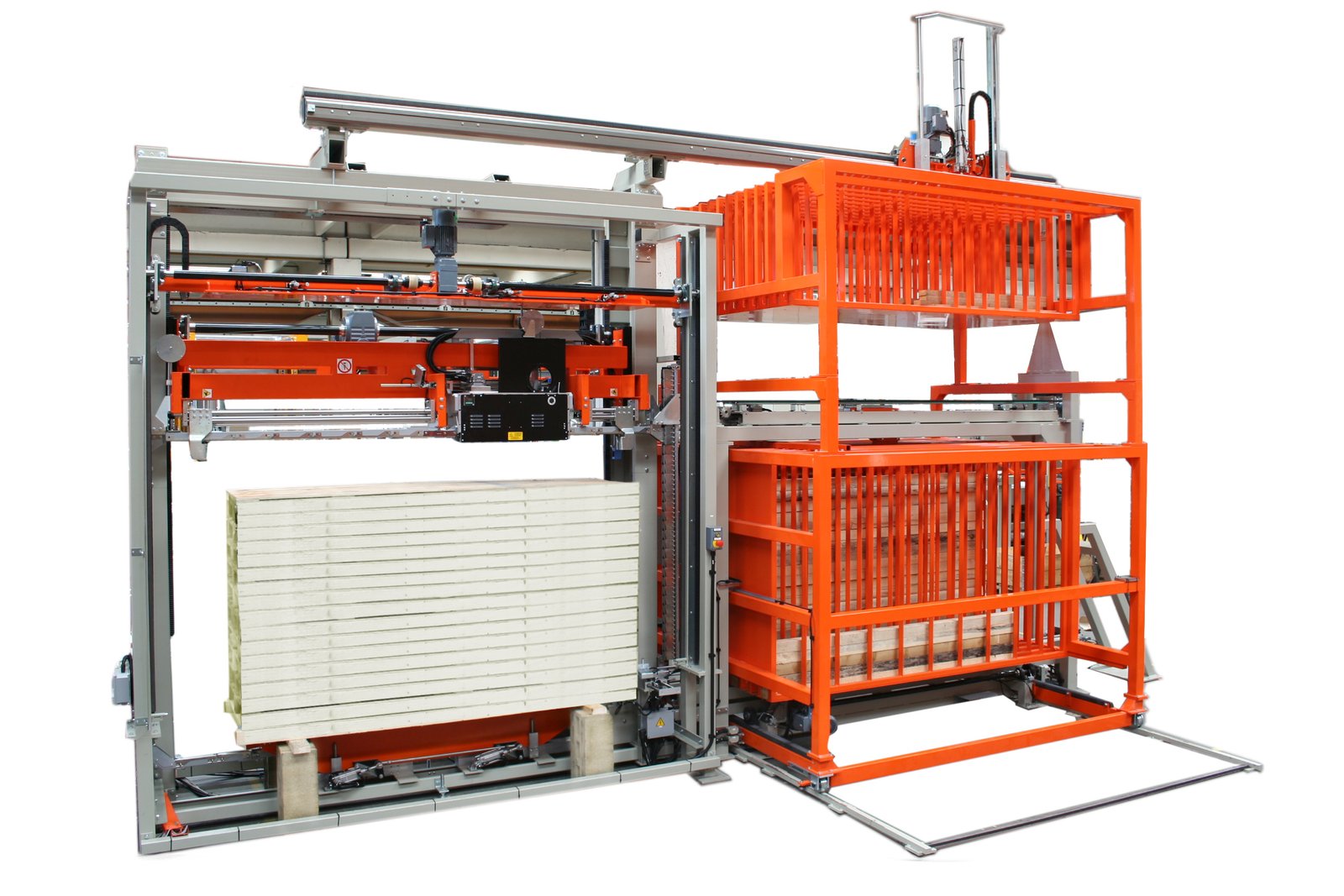

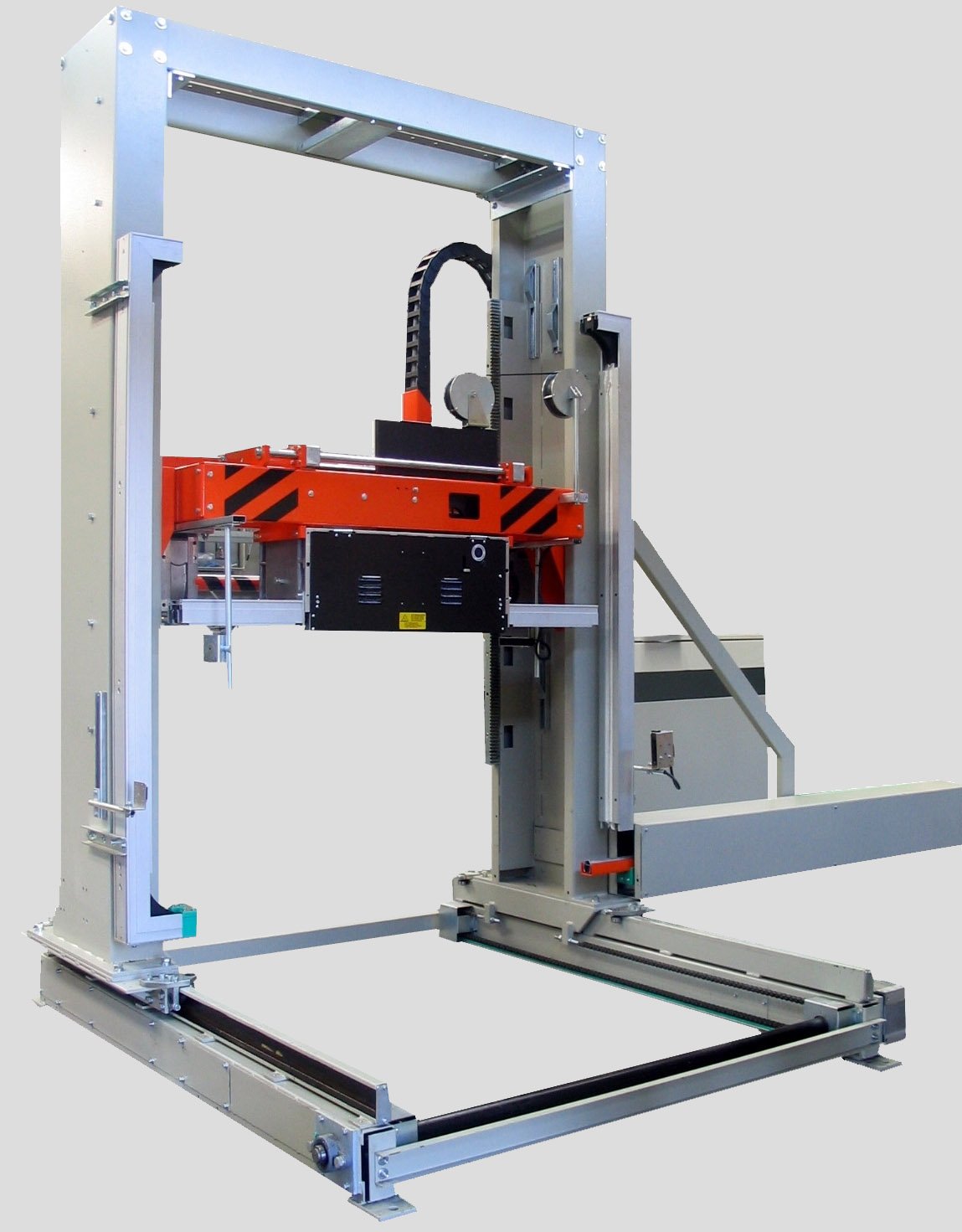

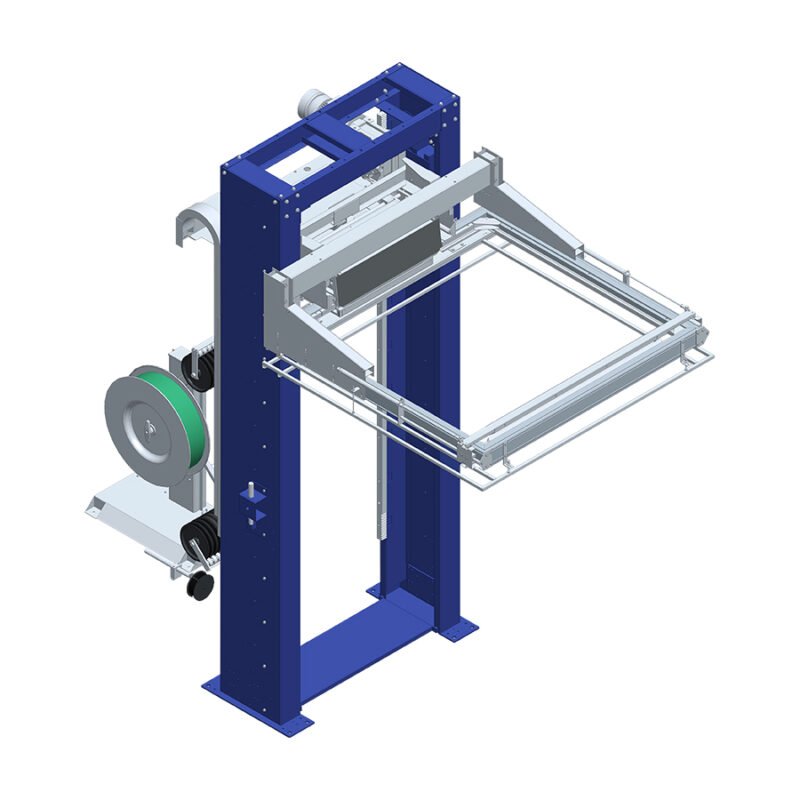

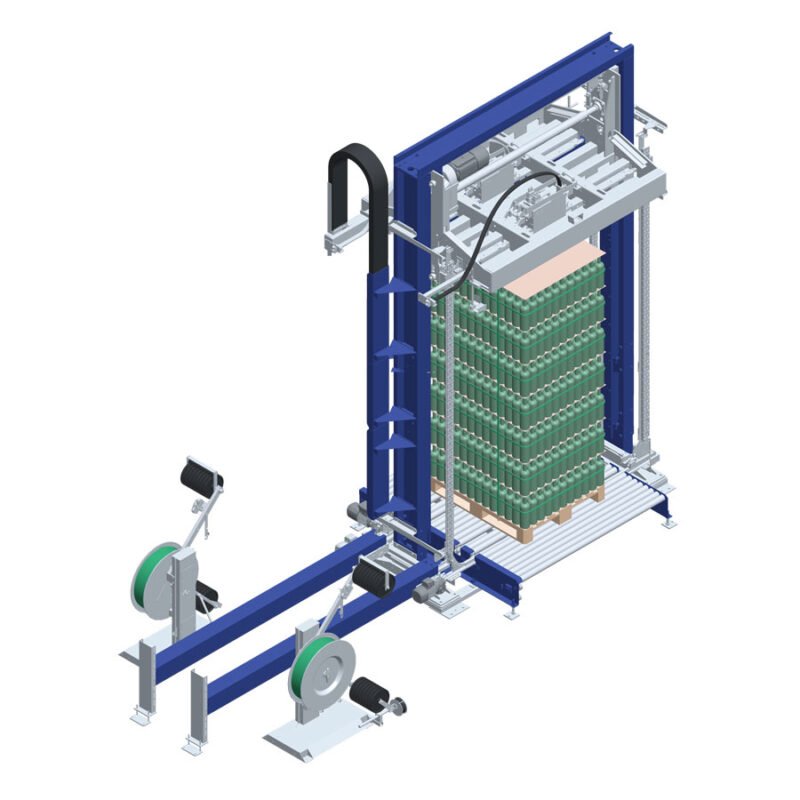

vertical strapping machine renders the packaging of packs completely automatic. It is possible to undertake one or more strapping operations using polyester of heat-sealed straps. The machine consists of a sturdy structure made of electrowelded steel sections, which support all the component parts of the entire strapping machine.

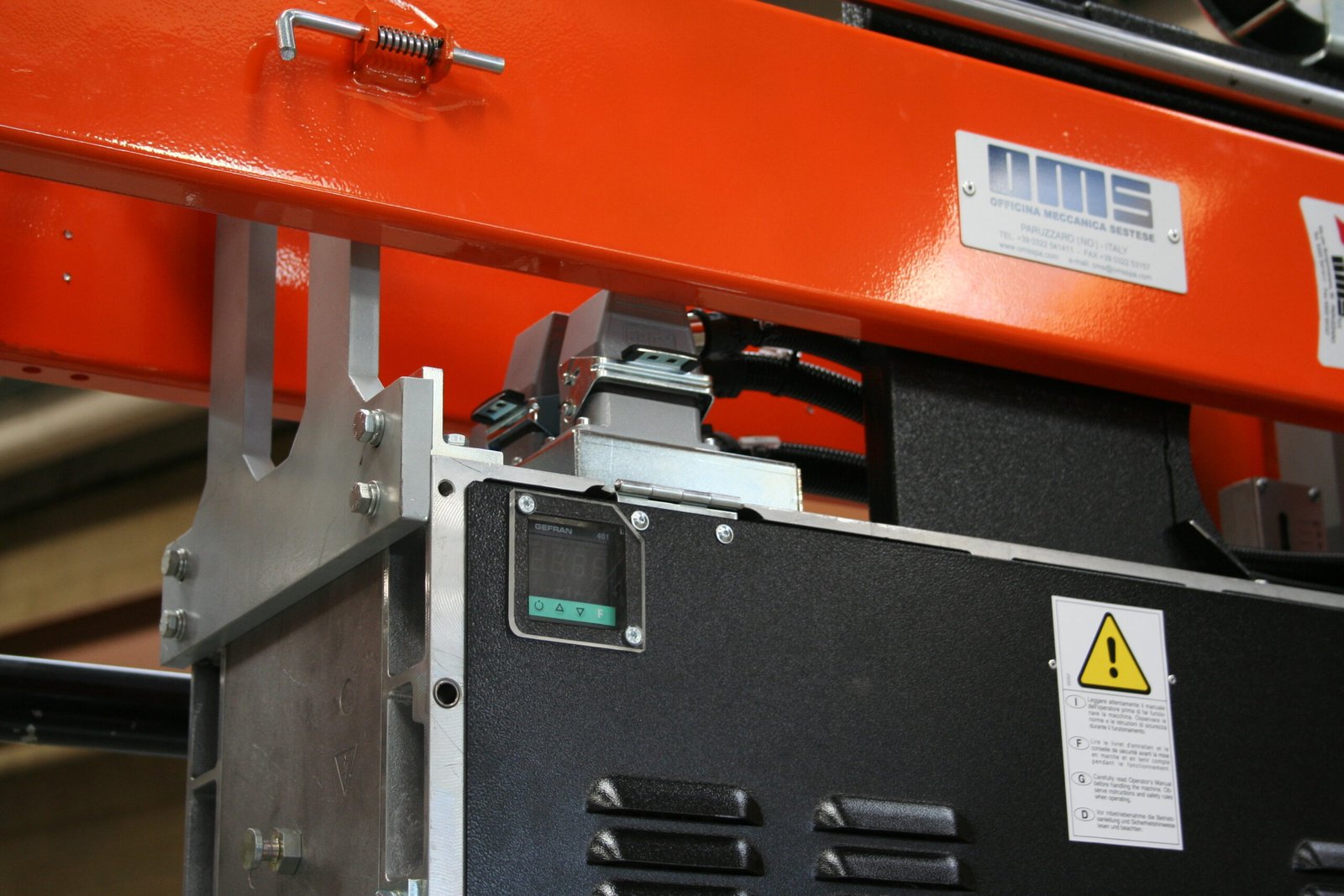

- The launch, recovery, tensioning, welding, and cutting processes are all automatically carried out by the Mod. TR head (our international patent).

- The strap sliding channel around the pack is composed of a unique material and has multiple independent sections with a release device to guarantee that the strap is perfectly centered around the pack.

- Head compensation device. This is possible through the cross-deplacement of the whole welding head during the tensioning phase. This assures the uniformity of the feeding on each side of the parcel. The deplacement of the same is possible by means of bearings that slide on treated guides.

- Strapping head movement unit, which lowers until it meets the pack. The cycle is automatically activated by means of a sensor.

- Strap feeder unit with roll-holders with cutting operation for removal of the same with anti-tear unwinding system and electromagnetic brake unit.

- Electric panel for the complete automatic function of the machine, complete with controls for manual operations.

- The entire plant is complete with all on-board installations (electrical and pneumatic) and is completely painted.

STANDARD MACHINE CHARACTERISTICS

- Strap Type: polypropylene (PP), polyester (PET)

- Strap union : thermoelectric welding

- Applicable strapping head: TR1400/TR1400HD/TR1800/TR2000

- Electrical Supply: 400/415V three-phase 50Hz

- Installed Power: 2,7 kW

- Coil-holder: inside diameter 390 ÷ 405 mm. width 150 ÷ 160 mm

- Air pressure: min 3 bar

- Side shifting device as optional

- Top, bottom and lateral bunk feeder as optional