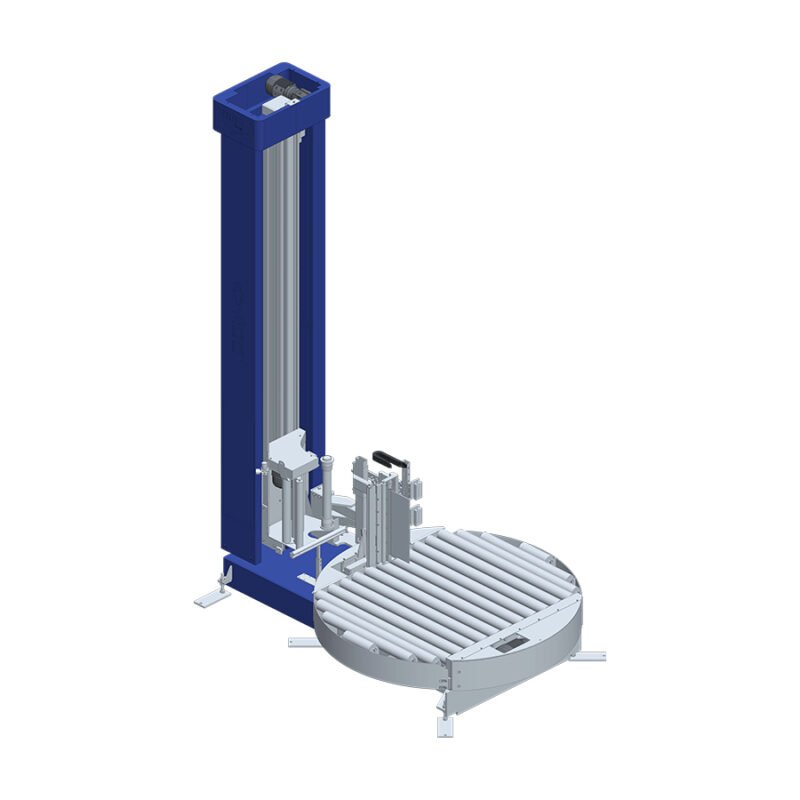

AVR900CS Automatic Ring Wrapping Machine

Automatic ring wrapping machine, ø3400 mm w/h single coil.

• The carbon “ring” technology allows the wrapping cycle to be carried out without moving the pallet and, consequently, without endangering its stability or damaging the load, while guaranteeing high production capacities.

• Possibility to start and stop the wrapping cycle at any height of the pallet load.

• Possibility to implement specific wrapping sequences and work cycles.

• A pre-stretching unit driven by a high-performance brushless motor to ensure the highest operation response. Possibility of adjusting the percentage of pull in all phases of the wrapping cycle and thus guaranteeing uniform load holding. The machine is supplied with a choice of 3 pairs of pulleys in order to obtain the following pre-stretching percentages: 100%/150%/200%/250%/300%.

• The film cutting and welding system is composed of a group with an infrared emitter. The welding cycle can take place at any point or at any height of the load, ensuring the absence of a film tail. Ideal solution for the storage of packaging in automatic warehouses.

• The tubular machine structure contains the counterweights that guarantee high operating speed and high reliability on suspended loads.

• The descent phase of the up-and-down ring frame is protected by a group of four photocells, which run a shape control throughout the downward motion.

• The cutting and welding advancement crosspiece is mounted on an anti-collision and anti-roll counter-frame in order to avoid any risk due to irregular loads.

• Use of standard and world-wide available components, compliant with EC safety standards.

Options:

Double coil (Twin)

– Gravity stabilizer press;

Roping device

Categories: Automatic, Packaging Machinery, Stretch Wrapping Machines

STANDARD MACHINE CHARACTERISTICS

- Hourly output: up to 80 packs/h (100 packs/h with Twin carriages version)

- Rotation speed adjustable: Up to 33 rpm

- Film roll width: 500 mm

- Film roll weight: Max 24 kg

- Film roll diameter: ø250 mm Max Outer / 76 mm Inner

- Film thickness: From 175 to 35 microns

- Electrical power supply: 3Ph, 400V, 50Hz

- Installed power: 9 kW

- Working air pressure: 5,5 ÷ 6,5 bar