Horizontal Strapping Machine /06C

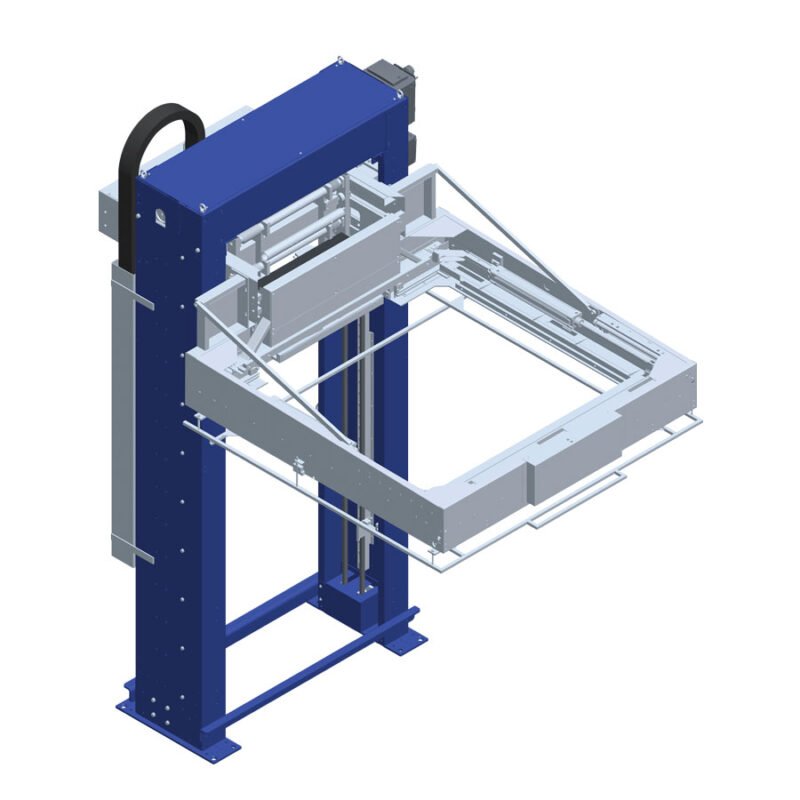

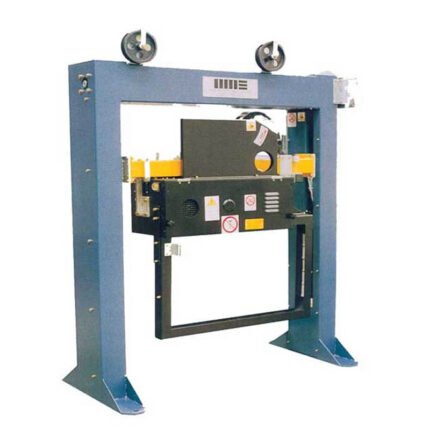

06C horizontal strapping machine

permits fully automated pack packaging. Polypropylene or polyester straps that have been heat-sealed can be used for one or more strapping procedures.

The machine is developed and engineered according to the most modern design criteria and equipped with all devices to automatically carry out all strap feeding, centering, recovery, welding, and cutting operations, as well as the strap compensation and tensioning device, in order to ensure uniformity on all sides of the pack.

This machine is easy to operate and performs well thanks to the strapping head of the TR family (our patent), the group of strap reel holders, and the touch screen control panel.

Pneumatic squaring-alignment device of the load fitted on the moving arch. This unit acts on the four sides of the package before each strapping, with a strength of clamping adjusting up to 2500 N. The floating system allows the squaring and strapping of loads not to be perfectly centered under the horizontal strapping area.

The machine is designed to be inserted in fully automatic lines, where it exchanges signals with devices installed upstream and downstream, or can operate in total autonomy

Categories: Full Automatic, Packaging Machinery, Strapping Machines For Pallet

STANDARD MACHINE CHARACTERISTICS

- Strap type: Polypropylene (PP), Polyester (PET)

- Strap union: Thermoelectric welding

- Applicable Strapping Head: TR1400/TR1400HD/TR1800/TR2000

- Reel holder: Inner ø 390 ÷ 405 mm, width 150 ÷ 160 mm

- Power supply: 400/415 V, 50Hz, Three phases

- Installed power: ~ 2 kW

- Air pressure: 5,5 ÷ 6,5 bar, ~ Nl 16/cycle