Automatic Side Strapping Machine/ 875AB

875AB

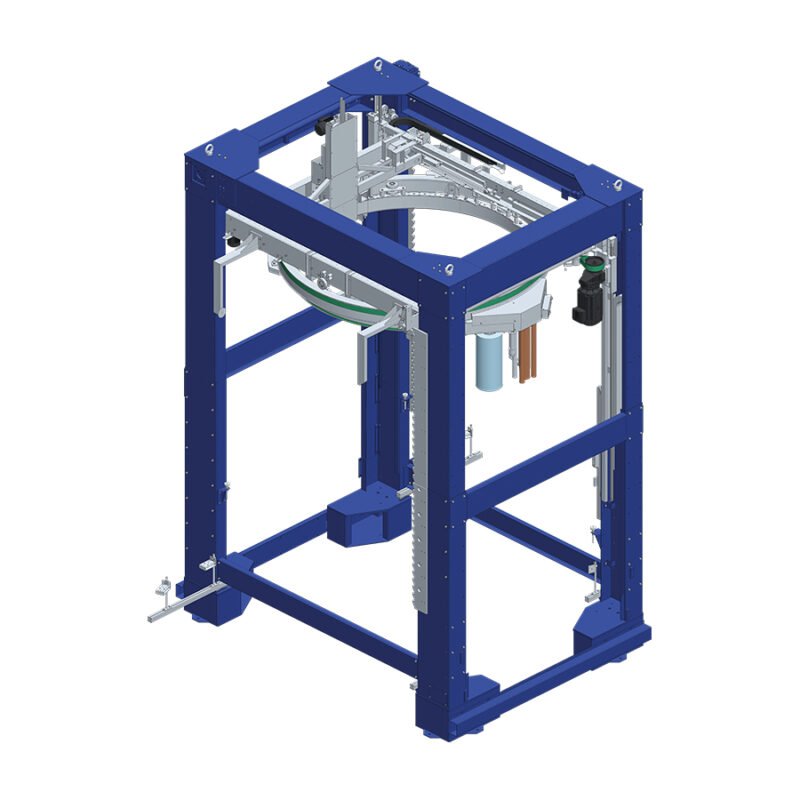

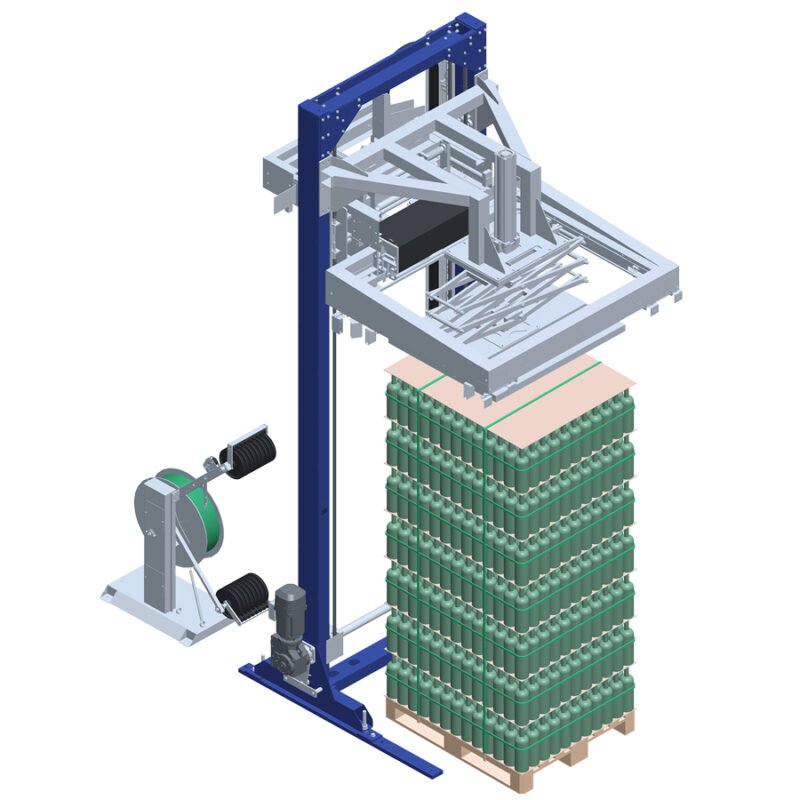

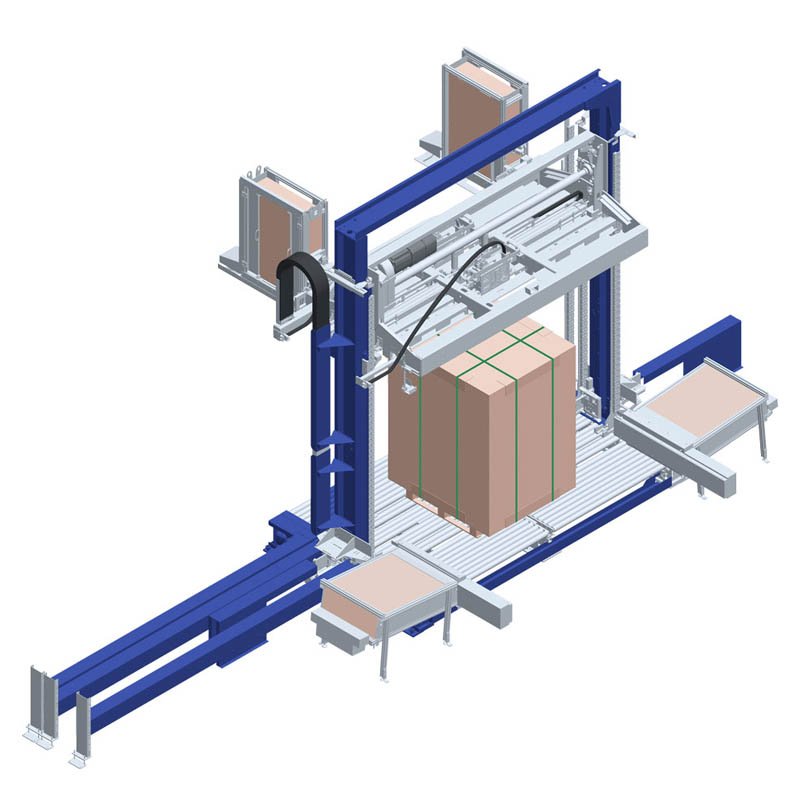

The automatic side strapping machine model automatically packs products of any shape with one or more thermowelding polyester or polypropylene straps. The machine consists of a sturdy structure made of welded steel and aluminum, which supports all the strapping machine’s components:

- TR head located to the side of the product’s direction of travel (our own international patent), which automatically carries out the strap feeding, recovery, tensing, welding, and cutting operations.

- Arch support structure made of aluminum profiles.

- The track for the strap to run around the pack is made of a low-friction material that is highly resistant to wear. The arches are equipped with a special releasing device with multiple independent segments to ensure perfect strap centering around the pack.

- Strap centering is further guaranteed by a system of guide brushes.

- Strapping the head advancement group to make the head advance up to where it meets the pack. Max. stroke: 400 mm. The cycle is automatically actuated through a sensor.

- Strap feeding group with coil holders, which collects the strap through an anti-tear system and electromagnetic brake.

- Electric panel to make the machine work completely automatically and manually.

The machine comes complete with all the drive systems (electric and pneumatic) and is painted in every part.