get automated shrink wrap machines in Gulfood 2025

The automated shrink wrap machines are essential tools for modern packaging lines, providing fast, reliable, and consistent sealing of products.

These machines use heat to tightly wrap items in protective film, ensuring they are secure, clean, and ready for transport or display.

Ideal for industries like food, beverages, and consumer goods, automated shrink wrap systems help businesses increase efficiency, reduce labor costs, and maintain professional packaging quality.

Best automated shrink wrap machines in Gulfood

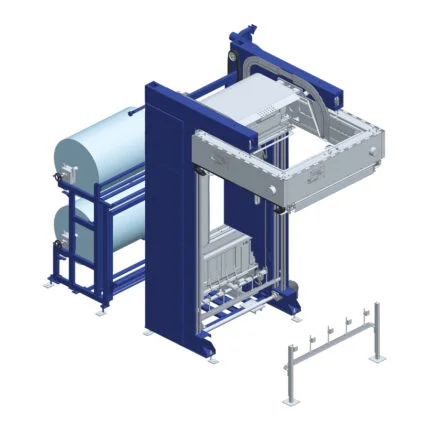

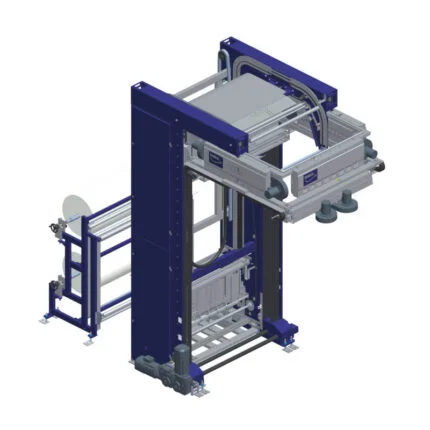

The machine is a fully automatic thermoshrinking-hooding machine designed for high-efficiency wrapping of pallets and large packages using tubular thermo-shrinking film.

It features an automatic film application system with a top-sheet dispenser and accommodates wrap dimensions of up to 1050 mm × 1250 mm × 1370 mm, with maximum load weights of up to 2,200 kg.

automated shrink wrap machines

The Future of Automated Shrink Wrapping at Gulfood 2025

As the packaging industry converges at Gulfood 2025, the spotlight is firmly on the next generation of automated shrink-wrapping machines, systems that deliver speed, efficiency, sustainability, and intelligence in one package.

The following points capture the key features and trends shaping this evolution:

- Automation & Industry 4.0 integration:

Today’s shrink-wrapping machines are moving far beyond simply “shrink the film then heat it”. Leading machines now incorporate IoT sensors, real-time data feedback, and even predictive maintenance algorithms.

This means fewer stoppages, more consistent output, and better alignment with smart production lines.

- Sustainability as a standard:

With regulatory pressure and consumer demand mounting, machines are being designed to use thinner, recyclable, or bio-based shrink films, optimized heat tunnels to reduce energy consumption, and modular designs that minimize waste during changeovers.

- Flexibility & modularity for diverse production:

Manufacturers increasingly require flexibility, varying product sizes, special packaging formats, multiple film types.

The new machines showcased at Gulfood will emphasize quick change-over, adjustable sealing/heat settings, and modular frameworks that allow future upgrades without full re-installation.

- Enhanced efficiency and throughput:

Automated shrink‐wrapping is proving to dramatically increase output while reducing labor and error.

Reports show these systems can cut film waste, reduce downtime, and offer consistent seal quality even at high speeds.

Why Shrink Wrapping Is Essential for Food and Beverage Packaging

Shrink wrapping is essential for food and beverage packaging because it provides strong protection, keeps products clean, and extends shelf life.

The tight film seals items from moisture, dust, and contamination, maintaining freshness during storage and transport.

It also enhances product appearance, helps bundle multiple items securely, and ensures tamper-evident packaging, making it a practical and reliable choice for modern food and beverage manufacturers.

Top Global Brands and suppliers Exhibiting at Gulfood 2025

Hadanco Packaging Solutions LLC is one of the top global suppliers participating at Gulfood Manufacturing 2025, showcasing its latest innovations in packaging machinery, including strapping machines, taping units, and thermo-shrinking hooding systems.

Top Global Brands :OMS

OMS is one of the top global brands in packaging machinery, known for its high-quality strapping, wrapping, and hooding systems.

The company provides advanced solutions designed to improve packaging speed, reliability, and product protection across various industries.

Its innovative technology ensures efficient performance and long-lasting durability, making OMS a trusted name worldwide in automated packaging.

Top Global Brands :OMS

Hadanco Packaging Solutions LLC is one of the top regional suppliers for packaging machinery and materials, headquartered in Dubai, UAE.

They cater to a wide range of industrial clients across the GCC, offering solutions for strapping, wrapping, taping and full-line packaging systems.

Their strong reputation, wide product portfolio and customer-oriented service make them a go-to partner for manufacturers looking to enhance their packaging operations.

types of Thermo shrinking Machines

There are mainly three types of thermo shrinking machines:

- Manual shrink machines

Operated by hand, suitable for small-scale packaging or low production volumes.

- Semi-automatic shrink machines

Combine manual loading with automatic sealing and shrinking, offering higher efficiency.

- Fully automatic shrink machines

Handle the entire process automatically, ideal for large-scale industrial operations requiring speed and consistency.

Applications of Shrink Wrap Machines in the Food Industry

Shrink wrap machines are widely used in the food industry to seal and protect products such as bottled drinks, canned goods, bakery items, and frozen foods.

They help preserve freshness, prevent contamination, and improve the appearance of packaged items.

Additionally, shrink wrapping is used for bundling multiple products together for easier handling, transport, and display in retail stores.

How to Choose the Right Shrink Wrapping Machine for Your Product Line

automated shrink wrap machines

To choose the right shrink‑wrapping machine for your product line, focus on these key factors:

- Your production volume and speed

Make sure the machine can handle your peak output without becoming a bottleneck.

- Product size, shape and variety

Ensure the machine accommodates your largest and smallest products and any shape changes in your line.

- Film compatibility and type

The machine must support the film types (POF, PE, PVC) you plan to use, with proper sealing and tunnel performance.

- Available space and integration

Check the machine’s footprint and how well it fits into your existing production line or conveyor system.

- Budget, cost of ownership and support

Consider initial cost, energy use, maintenance, and supplier service quality over time.

By evaluating these areas carefully, you’ll choose a shrink‑wrapping machine suited to your current needs and future growth.

Visit our booth at Gulfood 2025 and explore the latest automated shrink wrap machines

You can visit our booth at Gulfood 2025 and explore the latest automated shrink wrap machines.

Discover how Hadanco’s advanced solutions can enhance packaging efficiency, protect products, and reduce operational costs, all while experiencing live demonstrations and expert guidance from our team.

Contact us today to request a personalized quote

Contact us now to request a personalized quote and find the perfect packaging solution for your business.

Our team at Hadanco will provide expert guidance, tailored options, and competitive pricing to meet your production needs.

In conclusion, automated shrink wrap machines are a valuable investment for businesses seeking efficient, reliable, and professional packaging. They help protect products, speed up production, reduce labor costs, and ensure consistent quality.

By integrating these machines into your packaging line, companies can enhance productivity and maintain high standards in product presentation and safety.