OMS automatic shrink wrap machine for pallets

The automatic shrink wrap machine for pallets is an advanced technology used to wrap products on pallets in a tight and effective manner. These machines rely on using shrinkable plastic film, which is heated until it shrinks precisely around the products assembled on the pallet. This ensures the protection of the products during transportation and storage. The automatic shrink wrap machine for pallets is an ideal choice for companies looking for innovative packaging solutions that ensure effective product protection while reducing operating costs.

Benefits of using heat shrink machines for pallet wrapping

automatic shrink wrap machine for pallets

Using heat shrink wrapping machines for pallet wrapping offers many benefits to companies in various industries. Here are the most prominent benefits:

- Heat wrapping pallets ensures the protection of products from external factors such as humidity, dust, pollution, and damage resulting from collisions during transportation and storage.

- Heat wrapping contributes to securely stabilizing products on the pallet, reducing the risk of slipping or collapsing during transport.

- These machines operate automatically, reducing the need for manual intervention and increasing the speed and efficiency of the wrapping process.

- By reducing the need for manual labor and increasing efficiency, companies can reduce the costs associated with packaging.

- Heat wrapping gives products a sleek and professional appearance, contributing to improving the company’s brand image, as the product appears tightly and attractively wrapped.

- Heat wrapping machines can be adapted to wrap various sizes and shapes of pallets.

- Because the plastic film shrinks tightly around the products, the risk of loss or damage during transportation is lower.

Key Features to Look for in a Shrink Wrap Machine

When looking for a shrink wrap machine for sale, there are several features to consider to ensure you choose a device that suits your needs. Here are some key features to look for:

- Size and Dimensions of the Wrapping Machine: Make sure the size of the machine is appropriate for the size of the products you intend to wrap.

- Performance Speed: Speed varies from machine to machine, so choose a machine that provides a balance between speed and efficiency.

- Heat Type and Constant Heat: Some machines provide constant heating elements to ensure even heat distribution, which helps to achieve ideal wrapping.

- Quality of Materials Used in the Machine: Make sure the machine is made of durable and strong materials to last for a long time, such as stainless steel or durable plastic.

- Manual or Automatic Control: Some machines offer manual control, while others operate automatically.

- Compatibility with Different Types of Covers: Check that the machine supports different types of covers or films (such as PVC and PE), as this gives you flexibility in choosing according to the product.

- Pressure Control: Some machines have a pressure control feature, allowing you to control the strength of the shrinkage to ensure tight wrapping.

- Cost and Energy Efficiency: Choose a machine that is highly efficient in energy consumption to reduce operating costs.

Types for OMS Automatic shrink wrap machine for pallets

OMS automatic shrink wrap machines for palletss include several types that suit different needs in packaging operations. Here are the details of these machines:

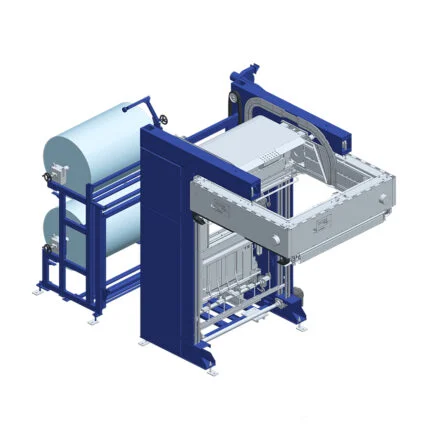

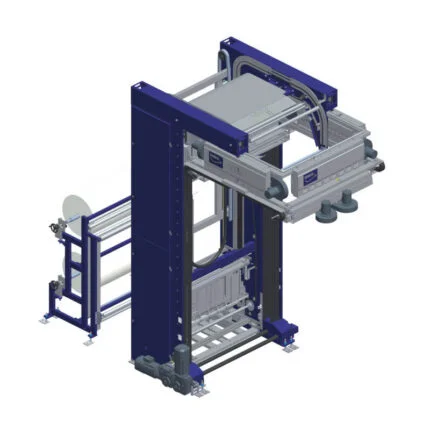

- Automatic Thermo Hooding Machine / AT53: A reliable machine for heat wrapping using advanced heating systems, providing safe and fast wrapping operations for various products.

- Automatic Thermo Hooding Machine / AT55: This machine features accurate and efficient heat covering for products, operating automatically to provide tight wrapping and avoid any problems related to uneven shrinkage.

- Automatic Thermoshrinking Oven / FT55: An advanced oven that operates with full automation, used in heat shrinking to achieve tight and effective wrapping for large products. This oven ensures consistent results at all times.

- Turntable Thermoskrinking Oven Machine / FT22: A specialized machine for heat baking with a rotary design that contributes to even heat distribution, ideal for wrapping products that require constant rotation during the shrinking process.

- Automatic Thermoshrinking Machine / FT53 TOP PAL: This machine uses advanced heat shrinking technologies that ensure even heat distribution, ideal for projects that require tight wrapping while maintaining the original shape of the product.

- Automatic Hooding Machine / AT53 GLS: Used to cover products that need comprehensive head wrapping, ideal for purposes that require precise wrapping on multiple surfaces.

How to Choose the Right Type?

automatic shrink wrap machine for pallets

Choosing the right type of Automatic shrink wrap machine for pallets depends on several factors related to the type of products, production volume, and packaging needs. Here are some points to consider when choosing the most suitable type for you:

- Choose the machine based on the size of the products; AT55 for small products, and AT53 GLS for head wrapping.

- For large production, choose FT53 TOP PAL or FT55, and for medium production, choose AT53.

- FT22 provides even heat distribution thanks to the rotary design.

- AT55 and FT53 TOP PAL provide high speed and efficiency in production.

- Make sure there is enough space available for large machines such as FT55 and FT53 TOP PAL.

- AT53 is flexible in handling different and diverse materials.

- FT55 is ideal for wrapping products that require high temperatures or special treatments.

Choose & order now OMS shrink wrap machine from Hadanco

Choose now the ideal Automatic shrink wrap machine for pallets for your needs from OMS via Hadanco, and get advanced technology and high quality to improve packaging operations in your project. Whether you need speed and efficiency in production or precise product wrapping, . Don’t waste time, contact us on whatsapp and order now and get the best solutions for effective and tight wrapping.

Automatic shrink wrap machine for pallets from OMS via Hadanco is the ideal choice for achieving high efficiency and superior quality in packaging operations. By choosing one of these advanced devices, you will have ensured improved productivity and guaranteed accurate and safe wrapping of your products.